|

PLANNING & BUILDING |

Deciding which shunting puzzle

to build - Layout size and prototype

modelled - |

|

PLANNING & BUILDING |

Deciding which shunting puzzle

to build - Layout size and prototype

modelled - |

| Planning and building a model railway layout is a tricky thing - there's no definitive way to get it right, but many ways to get it wrong. |

|

A fair number of clever and talented railway modellers with tons of experience have compiled some very helpful websites or written some rather smart and enjoyable books on the subject. However, even with a wide selection of different approaches and even modelling philosophies, a few basic rules remain the same: good quality track should be laid in a manner providing trouble-free running on a sound baseboard. |

| Whatever the building strategy, it is always a good thing to stop, look and check before getting on with the next step. |

| Deciding which shunting puzzle to build |

| Obviously, the first thing to do is to decide which type of shunting puzzle to build. Opting for one of the classics, an Inglenook Sidings layout is the most straightforward shunting puzzle layout that can be built due to its simplicity (which also makes it a rather cheap layout to build). |

| Building a Timesaver layout is, however, not much different apart

from a slightly higher degree of trackwork complexity

(and cost due to the higher number of turnouts (points)

needed). Or maybe you'd like to build one of the less often modelled shunting puzzles such as Linn Westcott's Switchman's Nightmare (actually a very early example, dating from 1956 and published in Westcott's classic 101 Track Plans). |

|

| Whatever your choice - before actually going about

any construction work, try to check that the complexity

of your choice matches what you'd like to see in terms of

an operational challenge. If you're not entirely sure

about this, an Inglenook layout is most likely the best

choice, not the least because you will be up and shunting

in next to no time. On the other end of the scale,

puzzles such as the Switchman's Nightmare are fairly

complex not only to build but also to operate, and

usually more suited for advanced modellers and puzzlers. Designing your own "new" shunting puzzle is another option, although you will find that usually elements of the two classics will creep in, and if you have a truly new concept you need to make sure it really works before fully assembling it in layout form. As a general rule, however, it is better to turn your own creativity to the setting and scenery for a classic shunting puzzle, rather than come up with your very own. But at the end of the day the only rule here is to set the points so you can travel on your own track of railway modelling fun. |

| Layout size and prototype modelled |

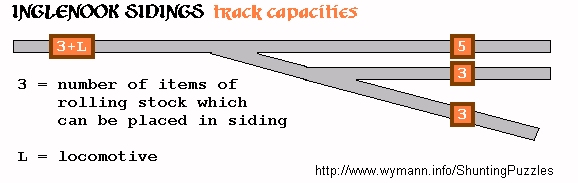

| Having chosen the shunting puzzle

type, the next question which needs to be answered is the

size of the layout. Because the rules of a shunting

puzzle are firmly linked to the length of the sidings in

terms of their capacity (i.e. how many items of rolling

stock a given siding must be able to hold), it is quite

clear that you need to know the length of the rolling

stock you will be using on the layout before making any

further steps. This in turn means that you have to settle on a prototype in order to be able to measure the items of rolling stock to be used on your future shunting puzzle layout. |

|

The length of an Inglenook Sidings type layout is easy to establish - it's a total of 8 times the length of the rolling stock to be used (5 in the uppermost siding plus 3 in the headshunt) plus the length of the locomotive to be used plus the length of the first point. |

| If you're really starved for space, or if the shunting puzzle layout will be a second layout which will need to live side by side with a larger layout which takes priority in terms of space, you might also consider a less common track configuration not necessarily known as a switching puzzle but which can be operated as one - the "tuning fork". The scene below on my HO Pecan Street layout fits into a width of no more than six inches (15 cm). | |||

|

|||

| But just how small can a traditional shunting puzzle a la Inglenook (actually, Timesavers aren't that much longer) get? | |||

|

|||

| This also explains why Z scale (the smallest commercial railway modelling scale) won't produce the smallest shunting puzzle layout possible. This is due to the fact that Marklin Z scale points are fairly generous affairs with a 490mm (1'1-1/4") radius. | |||

|

|||

| The bottom line then perhaps is to be careful not to be too greedy in terms of space - it's pretty much a law of nature that larger radius points are less likely to cause problems when used for repeated shunting and slow-running. No doubt medium and small radius points can work fine, but be sure to thoroughly check them before going much further in layout construction, because a shunting puzzle with frequent derailments and/or locos which stall on points and refuse to get moving again under their own power will not provide you with much fun. | |||

| Trackplan | |||

| Having determined the shunting puzzle type and layout size, the trackplan should now be a more or less logical affair. You can either follow the chosen shunting puzzle type's track plan very closely, or introduce some amount of variation, making sure that this injection of personal creativity doesn't interfer with the requirements needed to make the rules of the shunting puzzle work - although there's no reason, for example, why you couldn't cut down the number of cars of the Inglenook Sidings formula if you're building an indoor G scale version - the important thing is to make sure the layout is still "in balance". The late Carl Arendt, micro layouts expert par excellence, for example considered an Inglenook formula of 3-2-2 (instead of the original 5-3-3) to still be complex enough to provide interesting shunting orders. In the end, as with almost everything in railway modelling, it eventually boils down to a matter of taste. | |||

| One point to bear in mind which experience has shown

to be good railway modelling sense is to make sure the

trackplan and layout built from it allows for a

self-contained shunting puzzle without the need for any

add-ons to operate it - if at all possible. The trackplan shown here allows the shunting puzzle to fit on the 1'x4' baseboard completely, and even though it is designed to be extended at a later stage, it does not rely on these pipe dreams to become reality - it is a completely self-contained shunting puzzle layout by its own. |

|||

| The price for this - within the dimensions of 1'x4' - is that modern image is, by all practical means, ruled out as this layout size will only accomodate fairly short freight stock. If modelling standard gauge railways, this usually means turning back the clock to the steam/diesel transition era. | |||

| Baseboard | |||

| Now that the dimensions of the future layout have been worked out, it's time to turn to the question of baseboard construction. Although a shunting puzzle layout will usually be small enough to be portable in any case, it's good to bear in mind that the traditional method of building a frame from 4'x1' (10cm x 2,5cm) timbers usually results in massive and very heavy baseboards. | |||

|

|||

| Note that regardless of whether you build your own baseboards or buy some ready-made furniture to serve as base for your layout, "good quality" is the key word: only a durable baseboard which is level and won't warp will allow you to lay track which in turn is level and true - and stay that way. | |||

| Track | |||

| No model railway layout can really do with bad track, but when building a shunting puzzle layout, it's one of the most important things to consider. After all, you will want to be able to run locomotives and rolling stock at low speed back and forth and back and forth and so on. If the track on your layout won't allow you to do that more or less flawlessly more or less all the time, then your shunting puzzle layout will be just as much fun as missing the last train of the day at a lonesome country station in the middle of nowhere. | |||

|

|||

| For the major modelling gauges, there are many different makes of track available, and very often, the choice is a matter of personal taste and past experience. If you have neither, you will find hat the topic has been widely discussed in internet modelling fora. One aspect to take into consideration is that both on the real railways as well as in modelling terms track doesn't equal track. | |||

| In the UK the current standard steel rail used on standard gauge (non high-speed) mainlines is the so-called UIC 54 rail which weighs 113 lbs per yard (54 kg/m) and has approximately 2,400 sleepers (ties in US terminology) per mile of track. In places where the tracks are used less frequently and/or by less heavy trains, such as in yards, lighter rail is used for economical reasons. In the US rail weight can vary from 80-90 lbs (small yards) to 100-110 lbs (light duty track) to 130-141 lbs (heavy duty track, where 141 lbs is the new mainline standard). | |||

|

|||

| All of this means that simply by looking at the rails

it is often quite clear whether the track in question is

a modern heavy duty main line or a lightly used siding in

a yard laid decades ago. In modelling terms, this

translates into a wide selection of track. The choice between track with either wood or concrete ties (which obviously you do not want on a shunting puzzle) is now available even in Z Scale, and steel sleepered track is available in 00/HO, but far more important for a shunting puzzle are the various "codes" of rail offered, which refers to its height in thousandths of an inch. In the most popular modelling scale 00/H0 the different codes on offer are 100, 83 and 75, therefore indicating a rail height of .100", .083", and .075". |

|||

|

|||

| The choice of code is therefore not only dependent on aspects of reliability, appearance and compatibility, but also of prototype modelled. And don't forget that the track also has to deliver power to your locomotives. Even with DCC it's certainly a good idea to have a couple of power feeds even on a short layout. | |||

| Points (Switches) | |||

| Perhaps the most important aspect of track on a shunting puzzle layout are the points (switches in American railroad terminology), primarily because, for obvious reasons, they will have to work flawlessly. Applying extra care in laying, weathering and ballasting points therefore simply is compulsory. But before actually installing the points, you will have to decide what kind of points you are going to use. | |||

|

|||

| The reason for this is, of course,

that there is a horizontal force acting on the

wheels moving in a curve. We all know from practical

experience that objects which are in motion want to move

on in as straight a line as possible once they're moving.

In other words: rolling stock which is moving and sent on

to the diverging track of a point is actually set to

carry straight on. This conflicting situation also

produces additional friction force of the wheels on the

outer rail, which has to prevent the wheels from going

straight on - and derailing. Sharply angled points therefore put a lot of strain on the wheels of moving rolling stock, and unless you can move them really s-l-o-w-l-y, you will end up with far too many derailments to make operating the layout fun. The only way to reduce the horizontal as well as the friction forces is to choose points which flow more easily. If at all possible, try to avoid anything sharper than a #4 or 14 degrees frog angle (Peco "Streamline" points, both small and medium radius, have a 12 degrees frog angle but work fine from my own experience; on the other hand, Kato N scale Unitrack #4 switches are known to frequently cause derailments unless "tuned"). It should be remembered that shunting puzzle layouts don't by definition fall into the category of "micro layouts" - sharp points really should only be used if lack of space leaves no other option. The extra length this adds to the layout is well worth it. |

|||

|

|||

| Another aspect of points which used to be of some

importance and which continues to be a topic of heated

discussions is the difference between (to use the Peco terminology)

"electrofrog" points (which have a

"live" frog and require a certain amount of

wiring in order to change the polarity of the frog

according to how the points are set) and

"insulfrog" points (which have an electrically

insulated frog and require no extra wiring to operate) -

and which ones to use. Many modellers won't touch "insulfrog" points. However, the only reason why "Electrofrog" points were made in the first place was the bad electrical pickup in older models and subsequent stalling on electrically "dead" frogs. But since this is no real problem with more recent locomotives and older ones can easily be improved, the extra wiring required to switch the polarity of the frog in snyc with how the point is set seems rather a lot of trouble for no real gain - which is probably also why Peco introduced the "Unifrog" point in 2017; out of the package it will behave like an "insulfrog" point but the frog can be made to act like an "electrofrog". |

|||

| Some makes of points / switches, on the other hand, come with current carrying frogs and ready installed power routing, such as Kato's N gauge UNITRACK - the #4 switches come with factory installed power routing, but by simply changing a screw the switches can be set to be non-power routing, whereas the #6 switch is permanently power-routing. Other options exist for other brands and scales (such as Rokuhan's power routing points for Z scale), and it is worth checking before deciding on a specific product line. | |||

|

|||

Page created:

24/JUN/2002 |