|

| |

|

| |

|

|

Pecan

Street is

very much the result of "trial and

error": every now and then, something went

slightly wrong or didn't work at all - or I

simply changed my mind and approached things

differently. It's what I call "accidental

modelling". Here's an account of how

it all came together in the end, step by

step (which is why there is also a certain amount

of back and forth).

|

|

| |

Any

commercial products mentioned here are purely bona fide

indications of what I have been using myself.

I have no connection to any manufacturing companies nor

do I profit from listing any products or brands.

|

| |

|

| |

|

FIRST STEP: PROOF OF CONCEPT

|

|

|

| |

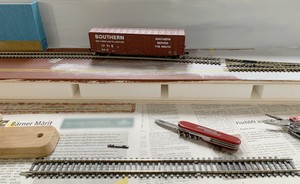

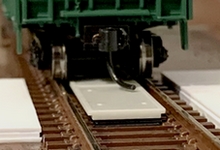

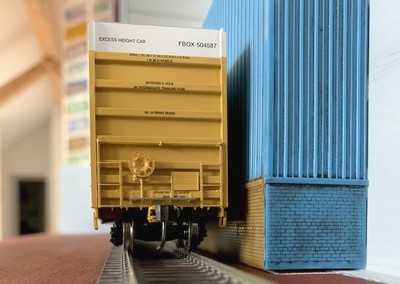

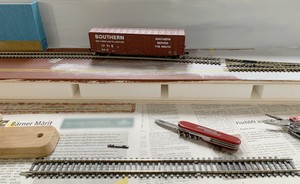

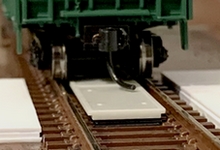

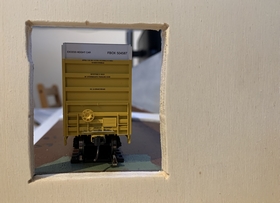

| The prime question that needed to

be answered was what two tracks within a depth of

only 6 inches actually looked like in the real

world - something that no track planning software

is truly going to be able to show. A piece of paper cut to the

required width served as a simple set-up for this

"proof of concept". It was always clear

that it was going to be tight, but the one thing

I didn't want was for it to feel overly cramped

(which is why a boxcar was set up on one of the

tracks).

|

|

|

|

| |

| This is one of those

"instant moments": either it clicks, or it

doesn't. In this case, I was happy to move on and

actually start building the layout. |

| |

| |

|

|

| |

|

|

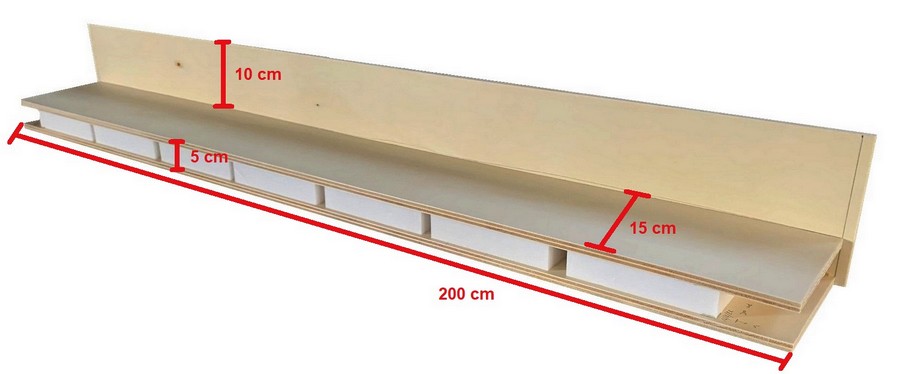

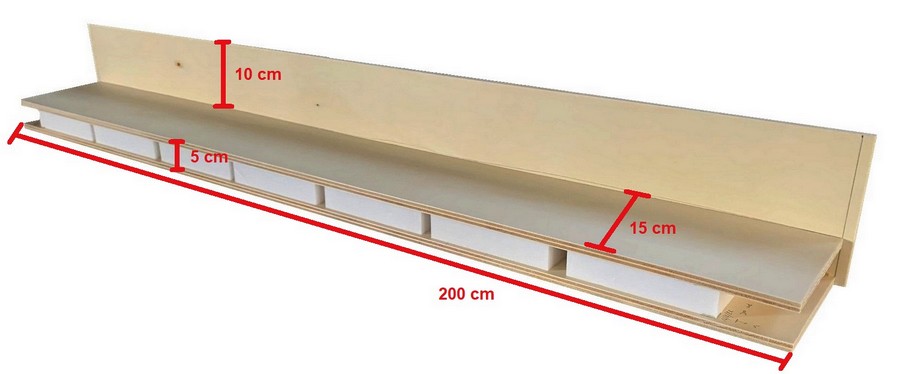

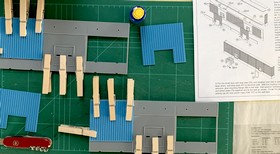

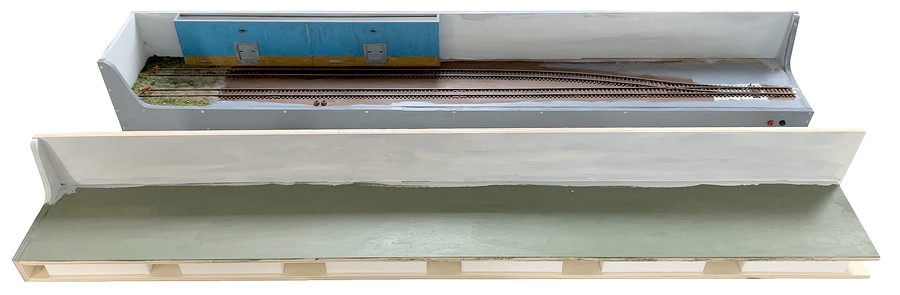

For the two

baseboard segments I returned to the construction

method used on Little Bazeley Mk2 which provided a solid yet

lightweight layout framework. Using a sheet of

10mm poplar plywood as the base, pieces of 20mm

styrofoam insulation are glued to that board,

which in turn is covered by another sheet of 10mm

ply in "sandwich style". Once

the side- and backdrop are added, this results in

a very sturdy yet lightweight layout frame and

basebaord (which also results in comparatively

silent running of trains).

There

is, however, one obvious problem with this

approach - there is no real cavity underneath the

trackbed-baseboard. In order to be able to run

cables underneath the baseboard top, the

styrofoam blocks are set back slightly, providing

some space at the front.

|

|

| |

|

| |

| |

|

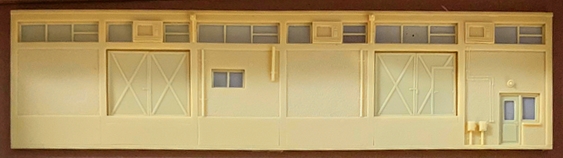

STRUCTURE #1: THE WAREHOUSE

|

|

|

| |

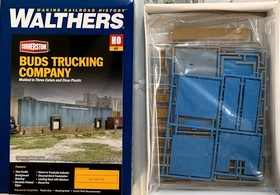

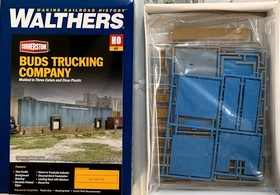

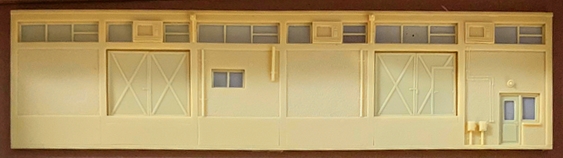

| Even though the restricted size

of the layout clearly limited the possibilities

for structures, I wanted the two tracks and the

shuffling of rolling stock to convey a certain

meaningfulness. Having a modern-style warehouse

as a backdrop and a "destination"

wasn't very orginial, but since I already had the

Walthers "thin profile background

building" (something I would call

"low-relief") it was both an easy and

convenient choice to make. At

1-1/8 inches (2.25 cm) the structure has a very

shallow footprint, yet its length of 19 inches

(48.3 cm) and its heigth of 4 inches (10 cm)

result in a fairly sizeable building, making it

all the more ideal for Pecan Street.

|

|

|

|

| |

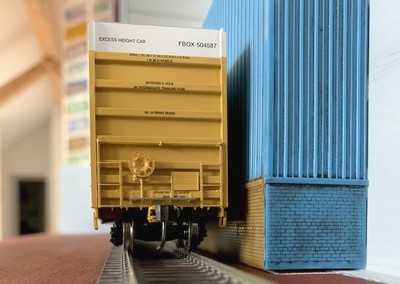

| Since clearances are all

important (and especially so if you only have 6 inches to

work with), assembling the warehouse was the first step

needed to provide a point of reference for where exactly

the tracks could go. At the same time, the baseboard

sides were added, and then a liberal coat of acrylic

paint sealed the baseboard top - track ballasting and

scenicking involves no small amount of a mix of water and

glue to fix it all in place, and baseboards that haven't

been sealed this way may well start to warp. |

| |

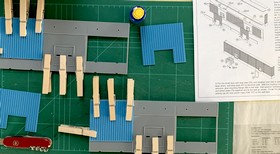

| The low-relief warehouse kit is a

very straightforward build, as was adding two

Walthers SceneMaster modern-style wall lamps

along with some initial weathering using Vallejo

grey and black wash.

Having

a narrow gap between rolling stock and the

warehouse front not only results in a more

prototypical appearance, it also provides more

room to space out the two tracks a bit, making

operation easier.

It

is important to be very diligent in this step,

using the widest and tallest item of rolling

stock along with all locomotives intended for use

on the layout, to ensure none of them fouls the

warehouse.

|

|

|

|

| |

| |

|

|

|

| |

| With all the clearances worked

out and marked down, it was time to lay the track

- once I decided which track to use. Peco is my track of choice

(due to decades of trouble-free running) but that

still left me with two options for an HO scale

layout: regular code 100 or code 83 US style

track.

While the code 100 track

has a slightly chunkier rail profile, the most

noticeable difference is the smaller size and

closer spacing of the ties, giving the code 83

version a distinctly more authentic

"American" look.

So why even hesitate?

|

|

|

|

| |

| The

sturdiness of Peco code 100 track is simply unsurpassed,

and since Pecan Street would require joining two segments

every time it would be set up (and then disconnecting

those segments again for storage), this seemed to be an

aspect worth taking into consideration. |

| |

|

|

Not that

Peco code 83 is overly delicate, but the finer

rail profile does make it feel somewhat less

bombproof in comparison. As an added bonus, using

code 100 track would allow me to fall back on a

short piece of Peco setrack - the ultimate means

of connecting the two segments in a sturdy and

reliable way. Code 100 track would also allow me

to run some older models with oversize wheel

flanges. As for the visuals, I had looked

into that a few years prior (for a US layout that

ultimately never materialized) by setting down a

50' boxcar on the code 100 track of my Little

Bazeley Mk1 layout. Not surprisingly, with no

code 83 track right next to it for direct

comparison, the weathered and ballasted code 100

track didn't look too bad, in spite of the

"wrong" size and spacing of the ties.

|

|

| |

| Ultimately, my decision was

helped by looking at prototype railroad locations around

warehouses - and seeing a clear and distinct potential

for hiding any perceived visual shortcomings of code 100

rail, since the tracks in those places often convey an

entirely different look than what can be seen on a

through traffic line. |

| |

| Looking north from a road

crossing on Titan Row in Orlando FL in 2021, we

see two modern warehouse structures served by two

sidings, along with a line that runs on to serve

more customers. The track

here is far from being dilapidated, in fact the

through track seems to have been re-ballasted

recently and ties replaced. But ballast on

industrial trackage often doesn't get tamped and

regulated the way it would on busier stretches of

railroad track.

As a result, ties often

get covered by ballast both to the sides of the

rails as well as in their center, and over time,

grass and weeds will grow up in places.

A dry run using a piece of

Peco code 100 track showed that emulating this

appearance on Pecan Street would minimize the

visual impression of the larger and more spaced

out ties.

As a result, I opted for

sturdiness and proven trouble-free running

qualities and chose Peco code 100 track for the

layout.

|

|

|

|

| |

| |

|

|

|

| |

| The simple track

configuration involved in a "tuning fork"

layout was thus laid using Peco code 100 track; Streamline

flextrack for the siding in front of the warehouse (since

this curves away from the single switch on this segment),

and pieces of Setrack "snap track" for

the siding running along the front of the layout (simply

because I had quite a stash of this available, and it

does make putting down a segment of straight trackage a

breeze). |

| |

|

|

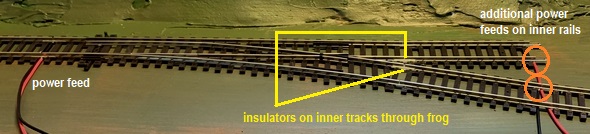

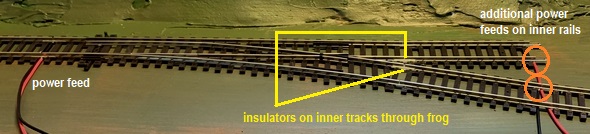

The switch is a Peco Streamline

medium radius "Insulfrog" point,

meaning it has an electrically insulated frog and

- unlike "Electrofrog" switches (that

have an electrically live frog) - requires no

extra wiring to operate, being DCC-friendly

straight out of the packaging.

The only snag that "Insulfrog"

points can throw up with DCC operation is a

potential shorting problem with some metal wheels

as they travel through the frog. Even though this

only seems to be the case with a very limited

number of wheelsets, I decided to play it safe

and add insulator joiners to the inner rails past

the frog (as per the instructions printed on the

Peco packaging of the switch).

The illustration below is

taken from my Little Bazeley layout, but the

principle remains the same for any layout.

|

|

| |

| Once everything panned

out, the simple track configuration was laid down in

virtually no time at all. I like to make sure that the

track is firmly and securely attached to the baseboard

(no roadbed needed for industrial tracks) before

weathering and ballasting, which is why I use Marklin Z

Scale track pins. Due to their very small size these are

very inconspicuous yet still hold the track down

perfectly well.

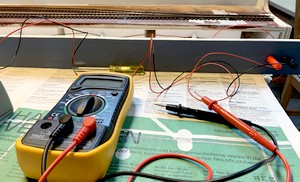

A

test run then makes sure that all electrical connections

work properly.

|

| |

|

| |

| There is also really

no difference in this case between an old-fashioned DC

wiring approach and a DCC friendly one. The only

difference are the additional feeder tracks

required due to the aforementioned insulator rail joiners

on the inner rails past the frog of the switch; I went

ahead and added additional feeders to both tracks at the

end of the two sidings to give this layout segment an

added boost in terms of feeding power to the track. All the wiring follows the common

colour coding of "black is at the back" (and

therefore red wires to the front rails).

|

| |

| |

|

|

|

| |

| As

a first step in weathering the tracks, I took the

baseboard outside and sprayed them a dark matt brown

colour using an aerosol spray can from the DIY store,

masking parts of the switch in order to avoid

conductivity problems. |

| |

|

| |

| Like

most modellers, I have accumulated lots of

"spare" items over the years, and I felt that

Pecan Street would be an excellent opportunity to use

items from this stash. |

| |

| However,

the rattle can that I still had left over from my

Little Bazeley Mk2 layout build a few months

back, proved to be a bad choice. The spray paint went on as usual and

without any problems, but when I tried to wipe

the top of the rails immediately after, I found

that the paint was too sticky to come off neatly

- or even refused to do so at all.

I suspect that the aerosol/paint/solvent

mix had deteriorated inside the half-empty rattle

can, but whatever the exact reason, I had to

apply a different approach than I usually would.

Deciding to let the paint dry completely, I left

it alone for a good 48 hours. After this, I used

swabs saturated with isopropyl alcohol to wipe

the top of the rails clean.

|

|

|

|

| |

|

|

This

worked well (and without the damage abrasive

tools inflict on the rail surfaces), although the

paint was a bit more stubborn in some places,

requiring two or even three swipes. In the end, however, this unexpected

problem was solved and all the rails had a shiny

surface (necessary to provide good electrical

pickup). The masked-off section at the switch was

then touched up with a fine brush and

rust-coloured acrylic paint.

In order to brake up the unrealistic

uniformity of the colour, I then added a few

touches of RailMatch's "sleeper grime"

(an acrylic paint) as well as some Vallejo

grey and black washes to the sleepers.

Even though this is a very

straightforward and simple way to achieve a more

realistic look, some (if not most of it) would

ultimately be lost - since I was planning to

"sink" the track and ties well into the

ballast. However, weathering the track really is

an essential part of recreating the atmosphere of

the real railroads, so I just went ahead with it

regardless.

More test running and checking of all

electrical connections after this stage is

essential to discovering (and if needed ironing

out) any bugs. Once the functional aspects of the

track are all settled, it's time to add ballast

to the weathered track.

|

|

| |

| |

|

|

|

| |

| Having ballasted model

track for a good thirty years in HO/OO, N and Z scale, I

felt confident that my array of proven methods

accumulated over that period of time would provide me

with a trouble-free part of putting together Pecan Street

- especially since for the first time I would not be

attempting to produce a well-maintained and neat looking

section of ballasted tracks. I was in for something of a

surprise - and an extended episode of accidental

modelling. Initially though, everything went according to

plan.

|

| |

Track

maintenance work at Abingdon Va, 15

October 2018 (Video)

|

|

The colour of ballast varies

greatly on the prototype, depending on

the type of stone used and how much soil

and rust is deposited on the trackbed by

traffic on the line. A little bit of

research into the area and era modelled

(on location if possible, otherwise

online and through books and other media)

really helps to get it right. Unless you are basing your

layout on a specific location with its

own unique characteristics, railroad

sidings serving warehouses in the US

commonly seem to use grey, light grey or

buff coloured ballast.

I have been

using Woodland Scenics ballast (actually

made from crushed walnut shells) for

decades and saw no reason to change that.

|

|

|

| |

| For

this layout, I opted for my favourite, the

"fine" grade light grey ballast (B74), which is

usually marketed for N scale and looks really good on HO

track. With Pecan Street, however, one fundamental aspect of

ballasting was different. |

| |

| Usually

(i.e. on all my previous layouts) I would try to

achieve a fairly neat appearance where the

ballast was evenly spread, with no loose

particles on top of the ties or clinging to the

rails. I would achieve this by sprinkling on only

small quantities from a teaspoon and then

straightening the ballast out using my index

finger, a fine paint brush, and a toothpick.

The basic idea is that you can always go

back for seconds and don't want to use too much

at once in order to avoid a mess. It's also at

this point that your Peco code 100 track

(dismissed as "toylike" by some

modellers) really starts to shine.

|

|

|

|

| |

| This

time, though, that "mess" which I would always

try to avoid was exactly what I now wanted for Pecan

Street. |

| |

|

|

What

I didn't bank on was that I would find myself in

a little bit of a mess of a different kind. In spite of not having to worry about

not getting ballast everywhere, I still tried to

apply some amount of restraint.

Once I was happy with the general look,

I proceeded to permanently glue the ballast down.

For decades I have done this using what

most modellers use: a mix of water and white glue

(approximately at a 1:1 ratio) with a drop of

washing up liquid (to break surface

tension).

|

|

|

|

| |

| The mix is then carefully applied

from a dropper, which proved a better choice here than a

syringe (both came from

the vet). The idea is to really soak the ballast, as this

ensures that the water/glue mix doesn't just cover the

surface. Mixing white glue

and water in this way is a time-tested method for

ballasting track, and once applied it's best to leave

everything to dry thoroughly for at least 24 hours. |

| |

|

|

And this is

when things started to behave quite unlike what I

was expecting from my past experience. To kick

things off, I found that the white glue I was

using dried perfectly clear, but with a distinct

and very glossy shine. While this would be great

if you modelled a scene during or after a

rainfall, it was not what I wanted.

Maybe

it was just that make of white glue. Common

modeller's wisdom has it that the cheapest white

glue you can get is the best for this, but after

testing out an additional two or three brands I

found that none of them really dried with a matte

appearance.

|

|

| |

| I

noticed that all the labels only specified that the glue

would dry clear but made no reference to a glossy or

matte appearance. |

| |

| On top of this, I then noted a

second, completely unexpected problem with the

stretch of track that I had already ballasted. Even though I didn't just throw down the

ballast with wild abandon, I found that after I

had soaked the mix of Woodland Scenics ballast

and scenic scatter material (still using the

"trusted" mix of white glue, water and

a drop of dishwasher detergent), it had a light

but still distinct tendency of expanding compared

to what it looked like in its dry condition.

The result was a bit more "ballast

and weed cover" than I had aimed for. While

the visuals were fine, I found that running a

"test car" (in the form of a Walthers

boxcar) over the newly ballasted track did reveal

two or three spots where the ballast interfered

with the wheel flanges.

It wasn't that big a deal

and easily rectified by scraping away the few

grains of ballast causing the problem. Any small

screwdriver or similar tool will do the job.

|

|

|

|

| |

|

|

In this case,

however, I used a cheap calculus scaler (I got

mine on eBay) that makes access easy and allows

for a pin-pointed removal of stray ballast. |

|

| |

| I was starting to realize

that, contrary to my initial assumption, covering

ties in ballast was actually more challenging

than creating a clean and neat spread of ballast

around the rails and ties. |

|

| |

| So

I made a point from this moment on of putting

down less ballast than originally intended,

especially between the rails. This would make sure there would be no

problems with wheel flanges, and potentially

"underdone" spots could always be

touched up later.

|

|

|

|

| |

| This

did not, however, fix the "white glue glossy

finish" problem. Was it possible that the formula

for white glue had changed across the board? Whatever the

reason, I quite unexpectedly found myself having to look

for an alternative solution. There were several options,

but I wanted something that wouldn't be too far removed

from what I had been using previously. And so I found

myself purchasing a container of Woodland Scenics Scenic

Cement™. |

| |

|

| |

| It solved my problem instantly, drying to a clear

matte finish and not "pushing up" the ballast.

For whatever reason (and it can't be too sophisticated),

this scenic cement worked while my trusted home-made mix

didn't. Of course there can't be too much of a difference

in terms of components (the scenic cement incorporates a

whetting agent, too) but since it worked and I wasn't

going to be needing gallons of it, that was all fine by

me. Sometimes there's nothing else to do but embrace

accidental modelling when it happens. From here on out, I

will be using Scenic Cement. Something

I never do, though, inspite of many positive reports from

other modellers, is "mist" the ballast with

isopropyl alcohol (IPA) before applying the water/glue

mix. Even when using a perfume atomizer, I have found

that no matter the distance from which the IPA is sprayed

on it tends to disturb the dry ballast - which is the

exact opposite of what this procedure is supposed to

achieve.

|

| |

|

|

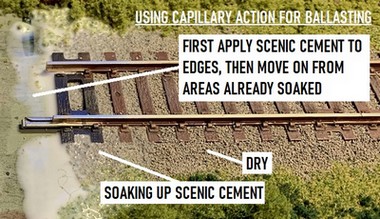

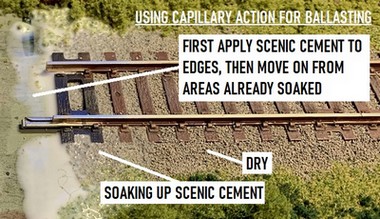

So instead of any

"pre-treatment", I simply apply the

scenic cement (or, previously, water/glue mix) by

taking advantage of its capillary force.

Because the scenic glue

has a lower surface tension than the ballast and

scenic material (thanks to the

"wetting" agent), applying the mix

close to the edge of the ballast (area #1 in the

picture) results in the watered down glue being

drawn in and seeping into the dry ballast by

itself - or rather by its capillary force (2).

Ultimately the effect is

similar to blotting paper or household tissues

sucking up liquids, and it leaves the ballast

almost completely undisturbed (3). The

illustration used here shows a piece of Z scale

track, but the principle obviously applies

regardless of scale.

|

|

| |

| Letting the capillary force do

its magic does however result in a slightly slower

procedure. Starting at the edges of the area to be

treated, patience is required to then let the scenic

cement work its way properly into the ballast and scenic

material (which might take a minute or two). Additional

scenic cement is then only applied to the areas which

have already soaked up the mix, saturating them to the

point where the mix then seeps into the adjoining area of

dry ballast and scatter material. It is definitely a

patience game, but then ballasting shouldn't be rushed

anyway. |

| |

| |

|

|

|

| |

| Since ballasting is best done in

stages over several days, I felt this was a good point in

time to assemble the second baseboard in-between

ballasting sessions. It's an almost identical twin,

constructed using the same methods a baseboard #1, except

that I opted for one less piece of styrofoam. Having six

of those instead of seven would give me more wiggle-room

to run the wiring. |

| |

|

| |

| |

|

|

|

| |

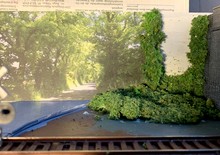

| Pecan Street obviously doesn't allow for a lot of

scenery, but what little could be done on segment #1

would be situated towards the backscene and fulfill two

purposes: convey an atmosphere of a more rural than urban

setting, and hide the fact that the warehouse is nothing

more than a flat frontage essentially just stuck right

onto the backdrop. Taken together,

those two points would ideally result in a number of

trees, but the layout simply doesn't allow for that, so

it would essentially have to be shrubbery and possibly

something akin to low-relief trees. It is this kind of

challenge that fuels my appreciation of theatrical

layout design, since art directors in the

entertainment business often have to work with similarly

restricted spaces, be it on a theatrical or a movie

production stage.

|

| |

|

| |

| Since the shrubbery will be "growing" up

from the baseboard top to the backdrop, providing a base

which provides an additional vertical structural support

will make it easier to bring the shrubbery up higher so

the required effect will actually work. This base is made up from four pieces

of narrow styrofoam. They are shaped to provide a slope

and then covered in a very thick layer of green acrylic

paint - normally I would cover the styrofoam with a layer

of plaster of Paris but this seemed like overkill in this

situation. When all will be done, nothing of that slope

should remain visible. The next steps on this will,

however, only be tackled once all the ballasting in that

area is done.

|

| |

| |

|

|

|

| |

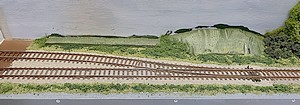

| Following the "heavy

ballasting" around the sidings, the area around the

switch was ballasted with a decisively lighter touch (and

therefore more in line with what I was used to from

previous layouts). The idea here is that the track is in

the process of being somewhat rehabilitated, as the

tamped ballast along with a small pile of fresh ballast

besides the switch is supposed to indicate. At a later

point, the two slabs in the background will support a few

lengths of switched-out worn and rusty rails. |

| |

|

| |

| |

|

|

|

| |

| The

narrow strip at the back of the left-hand section of

Pecan Street doesn't allow for much in terms of scenery.

The up side of this is that a lot less scenic material is

needed compared to what would usually be the case. The

possible down side: the scenery needs to be carefully

compressed in order to look convincing. |

| |

| I

have always built up my layout scenery in layers.

This allows for a gradual build-up and blending,

which avoids an overly uniform look and also

makes tweaking things a lot easier. The first stage in building up the

background scenery to the side of the warehouse

was to cover the styrofoam base with white glue;

this serves as a base for a generously applied

mix of Woodland Scenics "fine turf",

mixing "green grass" (T45, light to

medium green) and "weeds" (T46, medium

to dark green).

This produces a slope covered in low

grass of various shades of colour. It provides a

pleasing enough look, but more vegetation is

clearly needed. Adding different colour shades of

Woodland Scenics "bushes" (FC146 medium

green, FC147 dark green, and FC149 forest blend)

results in another layer, and a more

interestingly varied backdrop scenery.

|

|

|

|

| |

| Having more dark colours towards

the very back helps to accentuate the perception of

visual depth. For the most part, this second layer is

sufficient, since the background scenery is supposed to

be just that: its role is not to attract attention but

rather quite the opposite - to just blend in with the

backdrop (which, being of a deliberately toned down

"not so sunny sky" tone, also doesn't detract

from what is going on in the foreground). |

| |

|

|

Using

low-relief buildings imitates a stage trick and

is a prime example of theatrical

layout design. But in

order for this visual deception to work, it is

important to disguise the true dimensions of such

"stage props" - the unhindered view of

the shallow sidewalls of the warehouse meeting up

with the backdrop is a dead giveaway at first

sight.

The deception works as

soon as that view is obstructed, preventing a

clear visual perception of where exactly the

warehouse ends and the backdrop begins.

This is what stage

designers do both in theatres and on film

production sets, and in this case the effect is

easily accomplished by adding some sprawling

vegetation in the form of trees and tall bushes.

|

|

| |

|

| |

| This sprawling vegetation is

essentially a first layer; refinements can be made

anytime at a later stage. It is formed of Woodland

Scenics "bushes" (again

mixing FC146 medium green, FC147 dark green, and FC149

forest blend) and "foliage" made up of

various colours (F51 light green, F52 medium green, and

F53 dark green). |

| |

| |

|

|

|

| |

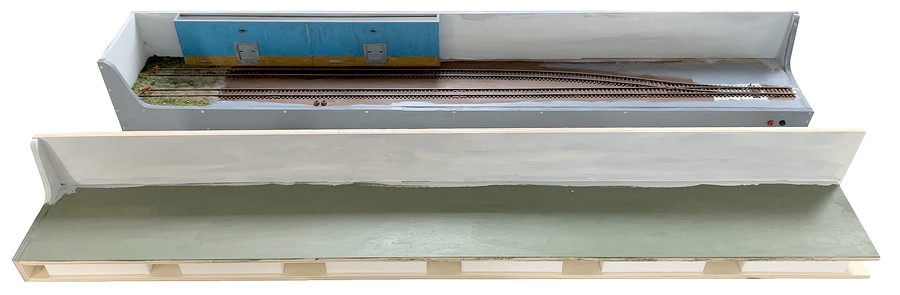

| With the left hand segment of the

layout having come along quite a bit, work started

shifting to the right hand segment - and with it the

question of how the two segments would ultimately be

joined up for operating sessions. Although actually, that

question had been answered long before, since the

possibilities of joining up the two segments with a piece

of setrack was an important point in going for Peco code

100 track. |

| |

| Previous experience with modules

has lead me to trade visuals for truly secure physical

and electrical track connections across segments, and

nothing beats having a short piece of track as a

"bridging" element. |

| |

|

| |

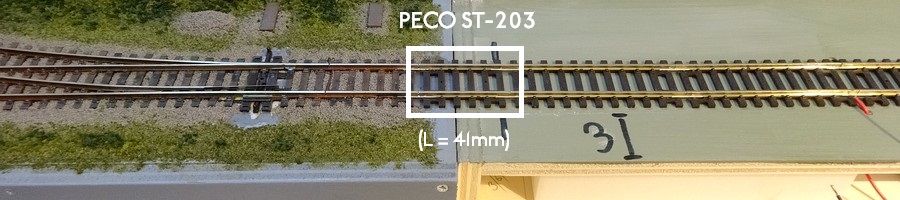

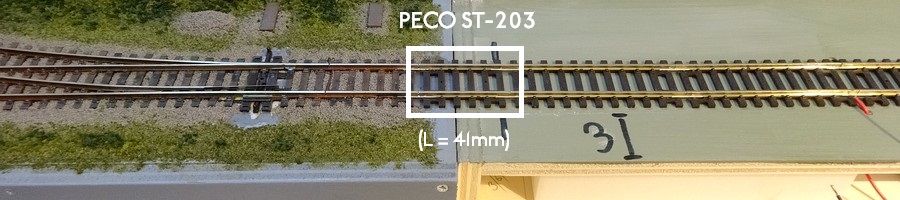

| The two segments of Pecan Street

are joined up by a very short (41mm) piece of track from

the Peco setrack range - a sturdy and reliable

connection. The tracks on both segments have been set

back accordingly in order to allow for a snug fit. Once

both segments are fully scenicked, the "connector

track" can be weathered in order to tone down the

visuals. |

| |

| |

|

STRUCTURE #2: THE COLD STORAGE

|

|

|

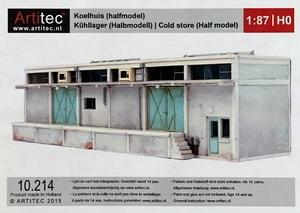

| |

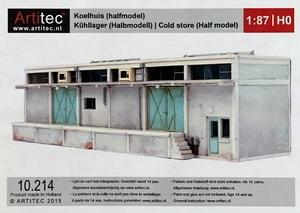

| A true "tuning fork" layout only has a

single lead track running up to the point, but early on

in my planning I decided to add some additional visual

interest and operational potential by adding another

point on the lead track with a very short spur that would

hold one single piece of rolling stock only. In order to give that single car spot

some sense of being another place that would have the odd

boxcar or mechanical reefer dropped off and picked up, I

decided to go for the Dutch company Artitec's low-relief

kit of a cold storage building that I had bought years

ago (and is no longer produced).

|

| |

| The kit is interesting in that it

is made from resin rather than plastic; this

allows for larger pieces with details moulded on.

|

|

|

|

| |

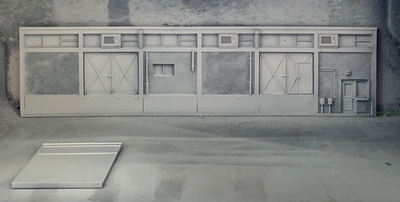

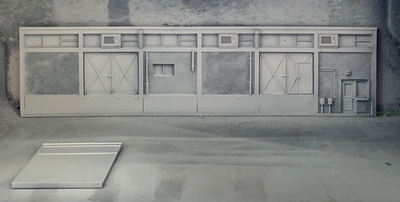

| As a result, the entire model is

made up of only a handful of parts. Somewhat inspired by

the rendition on the box, I gave the few parts of the kit

I would ultimately be needing two coats of paint from a

rattle can - the first black (for contrast and texture),

the second a light spray of white. |

| |

|

|

The

transformation from the original light yellow

colour is quite striking, and the rather finely

moulded details are nicely highlighted by the

darker shades from the first coat of spray paint. As

straightforward as this model is, it would need

some adapting to fit the reduced footprint

available on the narrow layout.

First

off, the already low-relief model was reduced

further in depth from the original 5cm to just a

tad over 2cm, resulting in a setup almost

identical to the warehouse scene on the left hand

segment.

To

give the model a bit more stability I cut a 2cm

thick piece of styrofoam to shape and glued it to

the back of the building's front

|

|

| |

| Since the

roof moulding didn't really work with the reduced depth

of the model, I replaced it with a simple piece of

styrene and then added the moulded loading platform and

canopy as per the instructions. |

| |

|

| |

| As

with the warehouse on the left hand segment,

getting the clearances right with this building

is the first step as these determine where

exactly the rails will go. And again the object was to get cars

fairly close up to the loading dock edge, as this

will eventually make things look a lot more

realistic.

Once the measurements were all in,

checked, and then double and triple checked,

laying the track was next.

|

|

|

|

| |

|

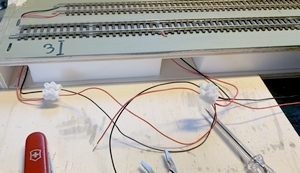

MORE TRACKLAYING & WIRING

|

|

|

| |

| Following the same procedure for laying track and

wiring it all up as on the first, left hand side segment,

the simple track configuration (which is indeed identical

to the one on the left hand segment) was again made up of

Peco code 100 track Streamline

flextrack for the siding in front of the cold storage

building and pieces of Setrack "snap

track" for the siding running along the front of the

layout. |

| |

|

| |

No changes to the switch arrangement

either, using a Peco Streamline

medium radius "Insulfrog" point and

adding insulator joiners to the inner rails past the frog

and extra wire feeds to all three segments of track, as

per Peco's instructions printed on the packaging of the

switch.

|

| |

|

|

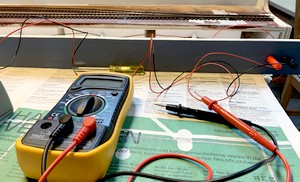

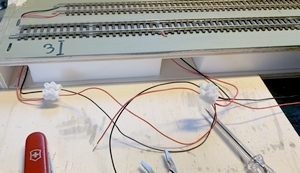

And again, Marklin Z Scale track

pins were used to attach the track firmly and

securely to the baseboard. Wiring such a simple track configuration

throws up no difference between an old-fashioned

DC wiring approach and a DCC friendly one -

although one could argue that the way I brought

together all three pairs of feeder wires has a

distinctly "old school" look to it.

After the all important

testing using a volt meter to make sure that all

connections work properly and provide eletric

current to all segments of the track, weathering

is next.

|

|

| |

BACK

TO WEATHERING THE TRACK

|

|

|

|

|

| |

| Avoiding the mistake of using the

contents of an old rattle can, I spraypainted the

rails, masking off (again, as always) the part of

the point which is made up of moveable parts and

also ensures connectivity for the elctrical

current. Painting the rails

outside on a hot August afternoon in the midst of

the 2022 heatwave made the paint dry really

quickly, so that it was impossible to wipe and

clean all the rail surfaces before the paint

started to set. But based on the experience with

the left hand segment, I knew not to worry and

just let the remaining paint dry properly. A day

later I used swabs

saturated with isopropyl alcohol to wipe the top

of the rails clean.

In order to brake up the unrealistic

uniformity of the colour, I also repeated the

process of darkening the ties, except this time I

only used a generous splash of Vallejo

black wash (which, when dry, is quite

transparent).

Once all is set for the moment, making

sure all electrical connections still work as

they are supposed to is certainly a good idea

before moving on to the next steps.

|

|

|

|

| |

| I

did this following my usual best practice (applying

current from a standard 1980s DC controller and measuring

the current in all relevant places with a volt meter) but

then also got out my old Roco/Atlas GP40 from 1984 for

some actual test running - just a simple moment of inspirational nostalgia. |

| |

|

| |

| |

|

|

| |

| Prior to ballasting a few scenic

items needed to be put in place, and one of them was a

grade crossing. Apart from

providing an opportunity to add some scenic interest, the

crossing was intended right from the start to mark a

boundary for switching moves when operating Pecan Street

in "tuning fork switching puzzle" mode. |

| |

In essence, it simply limits

the length of a train (and therefore the number

of cars that can be switched in one move) by

having a rule in place which states that the

grade crossing cannot be blocked during

switching.

|

|

|

|

| |

| For this layout, I made a point

of using as many items as possible that I already had

(i.e. purchased at one time "for later"), and

in my stash I found a number of concrete grade crossing

panels from BLMA (since taken over by Atlas). |

| |

|

|

The nice thing about these was

that they not only fitted my very approximative

era very well (they have been used since the

1980s), but also happened to be the same type I

observed in April 2022, at a crossing over a

single Norfolk Southern track at Memorial

Hospital in Roanoke Va. The

BLMA model consists of two center panels and four

side panels, but given the restricted space I

opted to use only half of these components -

which I would clearly have to raise a bit since

the packaging stated that they would work from

code 60 upwards.

|

|

| |

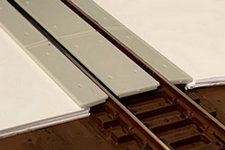

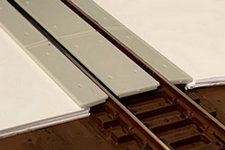

| The short stretch of road was

built up around the track using styrene sheets cut to

shape, and the BLMA panels brought closer to railhead

level using styrene shims. This is one of those occasions

where a delicate balance needs to be struck - setting the

panel in between the tracks too low will look terrible,

setting it too high will foul the couplers. As always

with clearances, it is best to use actual stock to make

sure things fit; in this case the central panel sits at a

visually realistic level - close, but not too close, for

couplers to clear it and run over it safely. |

| |

|

| |

|

|

The crossing will be guarded by a

pair of signals with working lights, using a very

nice brass item bought on eBay. Holes to accomodate the

signals are drilled, and the road is given a coat

of medium-light grey; this will serve as the

basis for some overall as well as detail

weathering later on.

|

|

|

|

| |

| |

THE

END (A.K.A. CONNECTION TO

THE REST OF THE WORLD)

|

|

|

|

|

|

| |

| In essence, Pecan Street is a

self-contained layout. And whilst there are no plans to

add any extension (such as connecting it to more modules)

for the foreseeable future, adding the possibility to do

so at this stage makes sense. |

| |

|

|

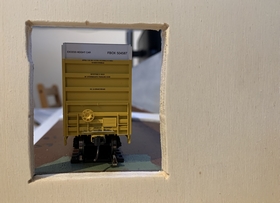

This also makes sense since there

is very little additional work involved in simply

cutting an opening into the sideframe (once again

making sure that the tallest and widest item of

rolling stock in use will pass through without

problems). On the layout

itself, a scenic break is needed to disguise the

actual end of the track regardless of whether it

can be extended beyond the baseboard frame or

not.

|

|

|

|

| |

| A chance discovery of a 2022

model of a low relief bridge from the Bachmann (UK) range

of "Scenecraft" resin models provided just the

kind of "scenic disguise" I was looking for.

Although intended for British layouts, the design seemed

a good fit for a layout based on an East Coast location. |

| |

|

|

In order to work visually the

depth of this very low relief model had to be

increased quite a bit. This

was achieved by adding a structure made up of

three pieces of styrofoam cut to size. The result

in itself is a very crude contraption, but since

the model covers it up, this is all it takes.

|

|

|

|

| |

| Black colour on the inside

disguises the styrofoam and creates enough of a

"dark passageway" feel to make it work as a

scenic break - one of many techniques I like to use that

originally stem from theatrical

stage design. For the moment, that was it; the

obvious rough bits and edges would be patched up and

hidden in scenery after the adjacent scene of the track

crossing had been worked on. |

| |

| |

STAGE

TRICK: THE CROSSING

|

|

|

|

|

|

| |

| The narrow nature of Pecan Street poses a number of

challenges, some of which have already been mentioned.

Most of those boil down to the fact that there simply

isn't a lot of room for scenery - and the grade crossing

is certainly one of the areas on the layout where this is

felt the most. I have also

mentioned how, in such cases, I like to fall back on

Frank Ellison's modelling approach involving theatrical

stage design - and this is perhaps also most apparent

in how the grade crossing is set up on Pecan Street.

|

| |

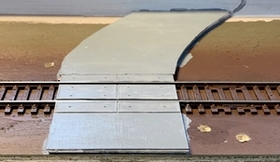

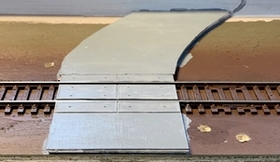

| In its raw modelling state, the

road crossing the tracks curves away slightly in

order to provide at least some illusion that it

doesn't just hit the backdrop in a head-on

collision, but it still clearly ends right there,

a mere 3.5 inches (9 cm) away from the track. In order to conceal this, a

number of steps would be necessary to create an

illusion of depth, and one central prop was a

rather nice model of a truck, manufactured by a

company named Boley, that I had bought cheaply

and put aside years ago for "some future

project". Now, it would literally take

center stage.

|

|

|

|

| |

| But before that could happen, the stage itself had to

be set. The idea was to add a flat photographic backscene

to the backdrop, and then add some semi-relief props to

make the scene look threedimensional and create the

impression that the road crossing the tracks actually

went somewhere in the background. After

finding a suitable royalty-free image on the web, this

was reduced to the required size, cut out and glued onto

sturdy 2mm cardboard, and given a protective layer of

matt varnish. This was then in turn glued to the

backdrop, and a first batch of scenic material applied to

cover both the edge of the card and fill in a gap between

the overbridge and the backdrop. For the more

three-dimensional props, two large scenic trees were cut

in half and then glued into place.

|

| |

|

| The trees

came from a range that can generally be

termed "cheap model trees from China

sold on eBay". They are somewhat

infamous for their overall identical

appearance (which of course explains the

cheap price) but also rather popular,

since it is fairly easy to improve their

looks. Usually the

excuse for giving these a go is the sheer

number of trees needed and the cost

involved, but I still happened to have

these lying around after a curiosity

purchase and successfully (I felt)

"pimping" them with Woodland

Scenics foliage for use on Little

Bazeley.

|

|

|

|

|

| |

|

|

Building up more layers of

scenery (mixing Woodland Scenics fine and coarse

turf, foliage and bushes of various colour

shades) allows the foreground to blend with the

flat backscene, further enhanced by some

strategic "shadows". As on a theatrical

stage, it is all aimed at deceiving the onlooker

into believing that the scene has more depth and

reaches further back than it actually does. The scene could be left this

way, but in order to fool even a lingering

observer a bit longer, the aforementioned truck

is placed as a view block which also deflects

attention from the flat backdrop to an actual

three-dimensional prop in the foreground.

|

|

| |

|

| |

| In order to achieve this illusion, some further

theatrical trickery is necessary - what seems to be a

truck is actually only part of one. Cutting

down the rear of the vehicule at a 45º angle not only

allows a longer vehicule to be squeezed into what little

space there is, it can then also be placed in a skewed

position (another theatrical trick for props that are

supposed to fool our sense of perspective).

|

| |

|

| Taking apart the truck for the

procedure was also a good opportunity to fit a

driver behind its wheel - a suitably cut-up

Preise figure from a set of track maintenance

workers. It's another stage setting adage: things

that are there may not always get noticed, but

things that are missing most certainly will. In a perfect world, I would

have turned the front wheels somewhat, but simply

thought of this too late - so I simply imagine

the driver is just about to apply the steering

wheel...

|

|

|

|

| |

| |

BACK

TO BALLASTING &

SCENERY

|

|

|

|

|

|

| |

| With the crossing scene set up,

the rest of the remaining portion of the second,

right-hand segment, was to be given a fairly

straightforward treatment in terms of ballasting and

background scenery. |

| |

|

|

So out came my array of

transparent household storage boxes, holding the

contents of various bags of ballast and scenic

material (mostly from the Woodland Scenics

range). The usual pieces of

styorofoam were cut, glued down and given a heavy

coat of dull green acrylic paint in order to

serve as contours for the background scenicking

in front of the backdrop.

As for the ballasting I

decided to generally keep it fairly neat on this

part of the layout compared to the warehouse

segment. The basic plan was to see how things

would look once completed that way, and then add

more ballast or weeds on top of the already

ballasted track if needed.

|

|

| |

|

| |

| Once

tamped down this way, more ballast can be added where

needed (which is a lot easier than getting rid of too

much ballast). It is impossible to avoid getting at least

a little bit of ballast where it shouldn't be (e.g.on the

sides of the rail), but all it takes to remove this is a

gentle approach using a fine brush and a toothpick along

with some patience. |

| |

| Once

everything looks okay, scenic cement is applied

from a dropper to the edges of the ballasted

area, letting the ballast and scenic material

soak it up thanks to capillary action. Adding

more scenic cement to areas already soaked in it

will make it "spread" to areas that are

still dry. Again, some patience is

required, but it doesn't take too long and causes

minimal disturbance to the unsecured ballast

grains (glue applied directly to dry ballast will

cause it to float and drift around). Since taking

advantage of capillary action for ballasting, I

have in essence switched from using a syringe to

a simple drop dispenser with a rubber teat, since

the latter provides a more controlled and gentle

application.

|

|

|

|

| |

| Again, the scenic ground cover is built up in steps by first

covering the painted styrofoam bases with white glue,

which in turn is covered with a mix of Woodland Scenics

"fine turf green grass" (T45, light to medium

green) and "weeds" (T46, medium to dark green)

in order to avoid a uniform look. Adding different colour

shades of Woodland Scenics "bushes" (FC146

medium green, FC147 dark green, and FC149 forest blend)

then results in another layer, which is secured with

scenic cement. |

| |

|

|

In order to

provide a smooth transition to the road crossing

scene, a short tree line needs to be built up

along this basic scenery - which means more

tweaking and pruning of some "cheap model

trees from China sold on eBay". |

|

| |

| Since this is strictly background

scenery and therefore explicitly not supposed to attract

attention away from the foreground, it's not about detail

but rather the overall impression. |

| |

| Tree stems

therefore do not need to be visible, even

more so since the trees are heavy and

dense in foliage (a real life example of

such a tree would be the Arborvitae

Tree). This in turn

means that I really cut into the

"plastic skeleton" of these

trees, leaving only a minimal number of

unconnected "branches" - they

won't be visible, but this provides just

the right amount of structural cohesion

and flexibility at the same time. The

cut-up structure of the tree still shows

off some of the very bright green the

tree originally comes in, but once it's

all turned around the Woodland Scenics

foliage hides practically all of that.

|

|

|

|

|

| |

|

| |

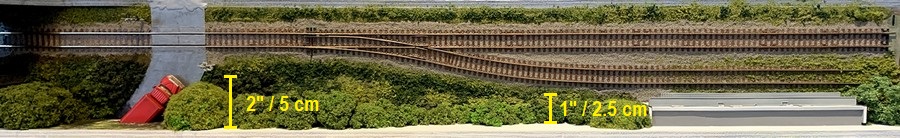

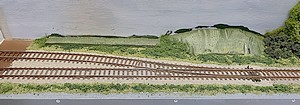

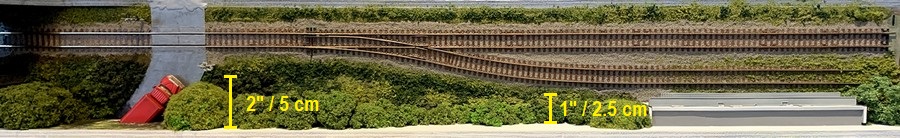

| Since the layout itself only has

a very shallow depth of 6 inches (15 cm), the background

scenery needs to be extremely compressed. It would be

almost impossible to fit an actual complete model of a

tree into a space of 2 inches (along the single track),

let alone into the cramped quarters of just one inch

(along the segment with the mainline and the spur).

Cutting up the trees is therefore very much the

equivalent of having super-low-relief structures (as,

indeed, the storage building on the spur is). |

| |

|

| |

| This also means that the tree line needs to be dense;

too much light foliage which would allow the onlooker to

see through the trees would be a dead giveaway. Stage designers have developed many

different tools to creating the illusion that a scene is

much deeper than it actually is, and this is just one

example of how applying theatrical

stage design to a layout works. Another trick of the

trade applies to hiding the true dimensions of low-relief

buildings. As with the warehouse on the left-hand

segment, an unobstructed view of the storage building on

this segment will clearly show that the side walls are

very shallow since they meet up with the backdrop almost

immediately.

In order to create the illusion of

an actual building that reaches further into the

background (as a real structure would) the view of the

side wall needs to be obstructed, This is exactly what

stage designers do both in theatres and on film

production sets, and in this case the effect is easily

accomplished by again adding some sprawling vegetation.

On the more visible right hand side of the building the

tree line meets up with it, along with some shrubs and

bushes. For the left hand side of the building - which is

in the far left corner of this segment and thus less open

visually - I opted for a more refinde model of an

individual tree.

|

| |

|

| |

| Unlike the cheap

quantity-over-quality plastic examples from China, this

one was hand-made in Vietnam using strands of wire to

simulate the bark and branches more realistically (as is

the foliage). Also available on eBay, these trees are of

a far superior quality, but obviously also carry a higher

price tag (you get what you pay for). The corner seemed a

good spot to "plant" such a model - visible

enough, but not too much. The tree is used as is, with no

cutting, and it does protrude slightly out into the spur

a bit, but since its location is the end of the line for

that siding, this isn't a problem. |

| |

| Building up

the scenery in layers like this also has

the distinct advantage that it's always

possible to go back and add more shrubs,

bushes, weeds and other items later on. But already at this

point, the background scenery fulfills

its purpose. It provides a setting,

disguises the otherwise obvious spatial

limits of the layout, and overall sets

the mood of the scene. And of course it

works best when there's something in the

foreground that shifts the focus of

attention.

|

|

|

|

|

| |

| |

|

| |

Text and

pictures are (c) 2022-2025 Adrian Wymann.

|

| |

page created 12 March 2022

last updated 31 August 2025

|

|

| |