|

| |

|

| |

|

| |

| The trackplan of a "tuning fork"

layout tends to be deceiving. The bare bones

simplicity of having nothing but an approach

spur, a switch, and two tracks beyond that, seems

to suggest very limited (if any) operational

interest. But that's because we tend to look at

such a simple trackplan the wrong way.

The operational "spice" of switching

a "tuning fork" layout is not generated

by the trackplan, but rather by the way the spurs

are switched - by using so-called car spots.

|

| |

|

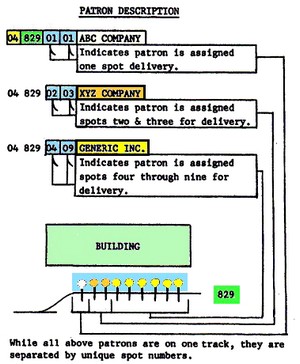

| Car spotting takes place where

one track (such as a single spur running

alongside a warehouse) either serves multiple

customers in that structure or has different

areas for loading and unloading.

Different

US railroads use(d) differing terminology for

this car spot designation system; the acronym

SPINS is an abbreviation for Southern Pacific

Industry Numbering System - it originated on

the SP but was also used by e.g. BN. CLIC (Car

Location Identity Codes) was a Santa Fe term

for the same thing, as was ZTS (Zone, Track,

Spot) on Conrail.

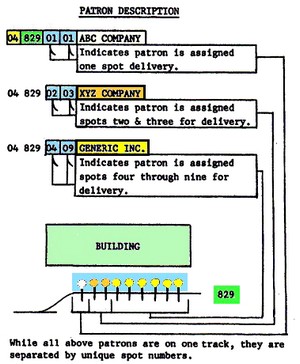

The example shown here (taken

from a 1987 Conrail ZTS for its New England

Division) explains it all quite well. If a

freight car is to be set out at 04-829-07, then

the ZTS map will tell any crew that its

destination is car spot 07 on track 829 in Zone

04, and that the customer in question is the

Generic Inc.

It is easy to see how requiring freight cars

to be placed in specific spots can add not only

additional realism to a switching layout but also

beef up the challenge of operating it

considerably.

And just like that, a single industrial spur

isn't that simple to switch anymore.

|

|

|

|

| |

| Pecan Street has five such car spots, two

directly in front of the warehouse and three on the

adjacent spur. The standard "tuning fork"

formula is expanded by the single spot at the cold

storage (C). |

| |

|

|

Applying the core idea of the

Conrail ZTS system, Pecan Street

provides the option to switch these car spots

with as many (or as few) cars and according to

whatever scheme comes to mind and hits your

operational fancy - you could use switching

orders, draw card orders, or even just make up

switching moves as you go along. |

|

| |

| In the real world and under normal circumstances, the

two tracks serving the warehouse would hardly ever see a

big congregation of boxcars, and this too can easily be

replicated. |

| |

|

|

Using car spots to determine

where rolling stock is picked up or dropped off,

the complexity of switching a "tuning

fork" will vary according to the number of

cars in use. Possibly just for the fun of running

a favourite locomotive and a few colourful

boxcars, this can provide a relaxing fifteen or

so minutes of easy-going operation. |

|

| |

|

| |

SWITCHING PUZZLE MODE

|

| |

| In order to operate a tuning fork layout such as

Pecan Street as a switching puzzle, certain constraints

must be introduced as to how many items of rolling stock

can go where. The number of car spots on Pecan Street

reflects the capacity limits of the two sidings; two

directly in front of the warehouse and three on the

adjacent spur, with a "free spot" on both

sidings.

In addition, switching puzzles also call for a

capacity restriction to the spur leading up to the switch

for those two tracks, i.e. the headshunt track - an

artifical complication of the situation. In real life,

the train crew might well be able to pull out all the

boxcars that would possibly fit on both sidings in one

move; by not allowing this, the puzzle aspect is

introduced.

|

| |

| After a few trial runs on paper,

I found that restricting the capacity of the

approach track to a maximum of 3 boxcars plus the

locomotive provided the necessary wiggleroom to

produce solvable puzzle set-ups; a lower capacity

(2 cars plus loco) can result in situations where

a boxcar gets stuck at the end of the longer spur

because it cannot be pulled. All of this

results in the "tuning fork switching

puzzle" formula "2(+1) / 3(+1) /

3+L".

|

|

|

|

| |

| The capacity boundary of the approaching track on

Pecan Street is marked by a road crossing, implying some

sort of a rule in place here that the crossing may not be

blocked for switching moves. The actual lengths of

track needed for this switching puzzle are, of course,

directly related to the rolling stock used. Since I

wanted 50' boxcars and second generation four-axle

road-switchers (e.g. an EMD GP38), this resulted in the

extended length of Pecan Street; using 40' boxcars and a

short locomotive (e.g. a GE 44t switcher) will reduce the

overall length of the layout considerably.

|

| |

|

|

At the start of the swicthing

puzzle, five items of rolling stock occupy all of

the five car spots. Each item of rolling stock

is then allocated a new car spot (in some cases,

this will coincidentally be the same spot it is

sitting in at the outset).

The goal of the puzzle (and thus the task of

the operator) is to switch the rolling stock to

the newly designated spots.

The car spots will most likely be decided by

an element of chance (e.g. by drawing car cards

or rolling a dice), but the rolling stock could

also be switched around according to requirements

set by the operator.

Things can be made more challenging by

introducing either an element of trying to keep

the number of moves to a minimum or by setting a

time limit.

|

|

| |

| Most of the time, this will prove to be a not too

challenging switching puzzle, although certain set-ups

can require some advance planning of the "pull out,

shove in" switching moves. In that respect, it is

not unlike an Inglenook

Sidings layout, albeit with a significantly reduced

complexity. |

| |

Overall view of the

warehouse tracks with a typical set-up on Pecan Street in

switching puzzle mode

|

| |

| Cars can be identified for spotting in many ways,

ranging from creating elaborate cards for every car

(which can be shuffled and then state which car needs to

go where) to simply using cars so that only one colour is

present and then just drawing siple slips of paper

stating the colour selected (e.g. "yellow car to

spot B3"). Even though it is unlikely that a

tuning fork switching puzzle will keep you entertained

for hours on end, it does provide the opportunity of

having short but pleasant interludes of operation on a

layout that does not take up a lot of space, is easy to

set up and store away, and can be built in a reasonable

amount of time and on a modest (or even minimal) budget.

|

| |

| |

|

| |

| |

Text and

pictures are (c) 2022-2025 Adrian Wymann.

|

| |

page created 12 March 2022

last updated 31 August 2023

|

|

| |